MOBILITY

TECHNOLOGY

TRANSFORMATION

GONDWANA AUSTRALIA is building the world’s most advanced SDV proving ground: an international digital mobility knowledge precinct where concept, development, validation, and certification run on a single, continuously connected ecosystem.

who is GONDWANA

GONDWANA AUSTRALIA is the world’s first Mobility 5.0 proving ground: a fully integrated, AI-driven ecosystem where concept, development, validation, and certification run as one. Powered by G-MATRIX AI—our real-time, AI-native operating fabric—we synchronise vehicles, infrastructure, and labs to turn every run into audit-ready, certification-grade evidence.

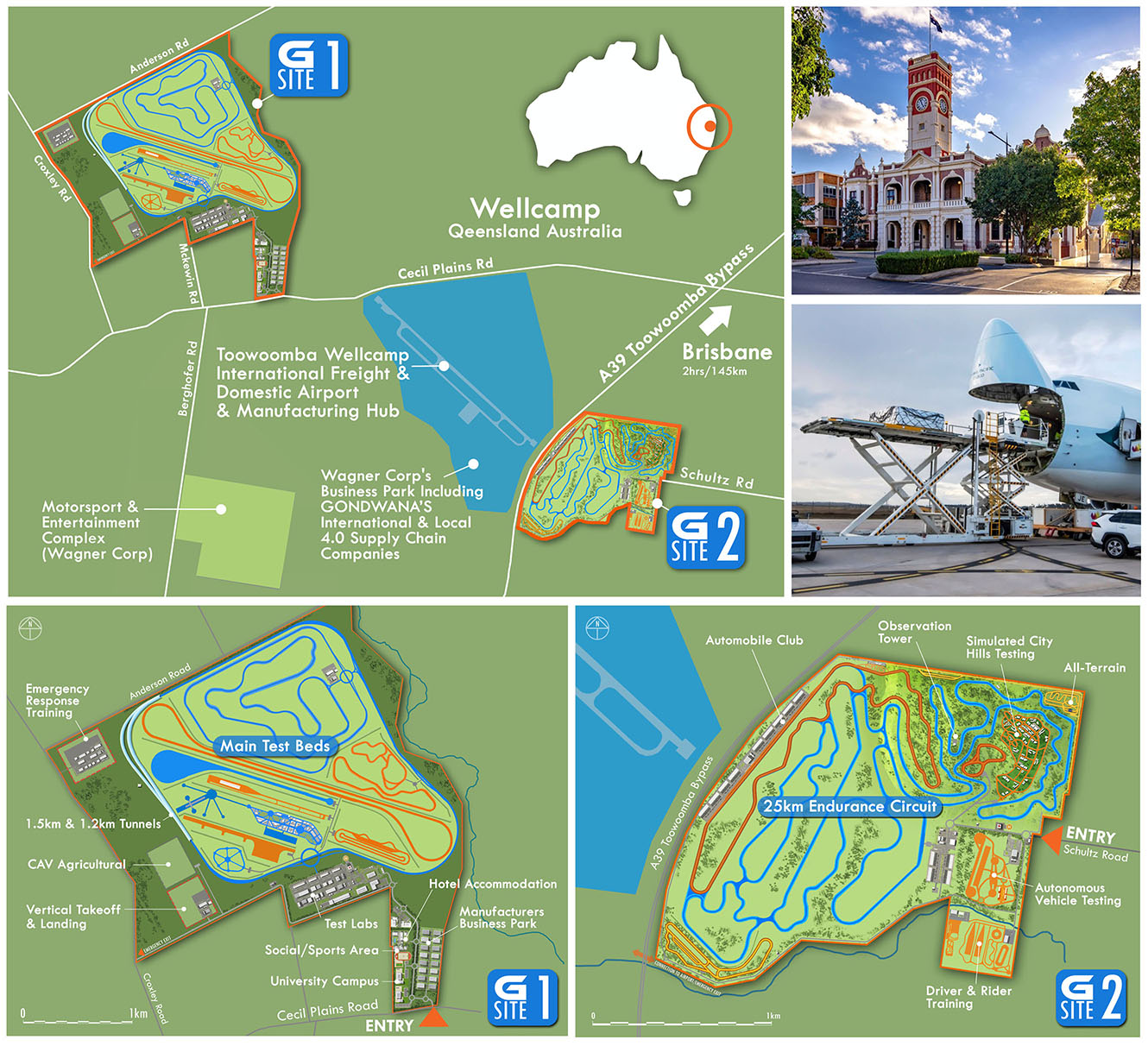

Across two adjacent sites in Toowoomba, Queensland (1,100 hectares, 24/7/365), GONDWANA unites 24 specialised testbeds and 100 km of instrumented circuits, including the 25 km GONDWANA TT endurance circuit, a live 16.5 ha hilltop autonomous township, programmable environmental tunnels, and an aggressive 18 km three-lane highway complex. Photonic TSN fibre, sub-nanosecond PTP timing, 5G-Advanced (future 6G), and MEC deliver deterministic replay and ultra-low-latency V2X—capabilities legacy grounds can’t match.

What we do: compress time-to-market and cost for software-defined, autonomous, connected, and electrified vehicles. We harmonise Shift-Left and Shift-Right using digital twins, deterministic orchestration, and programmable adverse-condition testing to reduce fleets, miles, false fails, and retests—producing globally portable, standards-aligned evidence.

Security and sovereignty are built-in: zero-trust client pods, PQC/PKI, SIEM/SOC/SOAR/XDR, and blockchain provenance protect IP and streamline multi-region compliance. With an on-site Mobility 5.0 university (SAE/IEEE) and a dedicated SDV-TIC provider, teams arrive productive and stay audit-ready.

Now in final design, GONDWANA invites foundation clients to shape remaining specifications before Q4 2025; operations commence Q4 2027. First in, best dressed.

THE PERFECT LOCATION

PRECINCT FLYOVER

WHAT WE OFFER

01

GONDWANA REVOLUTIONISING THE AUTOMOTIVE INDUSTRY

GONDWANA is at the forefront of a 5.0 revolution in the automotive industry, providing state-of-the-art product development and homologation testing. Our facility offers comprehensive services within an internationally recognized mobility knowledge precinct, featuring cutting-edge engineering and advanced manufacturing capabilities. Supported by a responsive ‘A’ class supply chain, GONDWANA includes an automotive homologation test site that meets rigorous international testing standards and supports SAE Automation Levels 1 through 5.

The world’s most advanced SDV proving ground—transforming the virtual digital chassis into the physical SDV in a secure real world development, testing, and validation centre to enable next-generation ‘autonomous, connected, and electrified vehicles.

- 24 specialised testbeds connected by 100 km of instrumented circuits for end-to-end workflows—from concept to homologation—in one secure location.

- A Mobility 5.0 university (with SAE International and IEEE) and on-site SDV-TIC operations to maximise throughput, reduce witness days, and streamline compliance.

- A secure, adaptive, multi-tenant digital backbone for deterministic testing, repeatable outcomes, and certification-grade data.

A Proving Ground Designed for Mobility 5.0

- G-MATRIX AI: An embedded, interconnected AI fabric aligning track assets, labs, test-houses, and vehicles for deterministic orchestration and sub-microsecond closed loops.

- Photonic TSN fibre rings with sub-nanosecond PTP timing correlate SIL, HIL, and on-road results—reducing runs and increasing coverage per run.

- Embedded V2X fabric with 5G-Advanced, future 6G microcells, and MEC for ultra-reliable low-latency communications and secure, observable vehicle-to-cloud workflows.

World-Class Test Environments

- GONDWANA TT Circuit (Site Two): 25 km endurance loop, 145 precision corners, 200 m elevation swings, straights linked to a 3 km wet circuit with a 100 m gradient topology.

- Live Autonomous Summit Township: 16.5 ha active suburban testbed on a 16° average incline—complex gradients, occlusions, and mixed traffic with deterministic replay for SAE Levels 1–5.

- Aggressive Country Highway (Site One): 18 km three-lane highway threading 1.5 km and 1.2 km two-lane environmental tunnels, connected to a 5 km programmable wet circuit.

- Environmental tunnels: Deterministic climate control for programmable thermal, humidity, weather, glare, dust, and low-traction conditions—replacing weather-bound calendars.

End-to-End SDV Workflows

- Onboard controllers ingest microsecond-synchronised telemetry to adapt torque vectoring, stability, and energy management in real time—mastering gradient changes, camber shifts, and surface transitions under repeatable, certification-grade conditions.

- Unified evidence fabric connects simulation, bench/rig, SIL/HIL, lab, track, and on-road testing—producing standards-aligned, reusable evidence globally.

- Shift-Left: Harmonised, time-synchronised schemas (TSN) port component, software, and vehicle-in-the-loop results directly to track—no adapters or reconciliation.

- Shift-Right: Deterministic replay and programmable adverse conditions generate repeatable edge cases—compressing mileage, driver hours, and prototype counts.

- Digital twins: Scenario libraries and facility twin accelerate learning cycles, deliver higher coverage, and reduce redundant tests across variants and releases.

The G-MATRIX AI Advantage

- Deterministic AI fabric: Turns every run into certification-grade, audit-ready evidence for homologation.

- Real-time orchestration: Sub-5-microsecond edge-to-vehicle latency enables tight, repeatable closed loops and precise replay.

- Reduced OpEx: Fewer fleets, fewer miles, fewer false fails—accelerating validation and homologation beyond legacy facilities.

- API-first architecture: Vehicle-to-cloud, signal-to-service, container-ready, with third-party API integration for rapid partner onboarding and interoperability.

Security, Sovereignty, and Compliance by Design

- Sovereign multi-tenant client pods with zero-trust, role-based access, PQC and PKI, encryption, SIEM, SOC, SOAR, and XDR.

- Federated learning and in-fabric edge compute keep heavy data local—shrinking public cloud egress without compromising security or speed.

- Tamper-evident evidence chains and blockchain-backed provenance for audit-ready submissions across jurisdictions.

- Built-in observability and secure APIs enable complex multi-tenant programs without IP leakage.

Location, Infrastructure, and Operations

- Two adjacent sites spanning 1,100 hectares in Toowoomba, Queensland—operating 24/7/365 under independent management.

- Airport-adjacent: Immediate access to a 24/7 international heavy-freight and passenger airport—reducing logistics lag and expedite costs.

- Industry 4.0+ ecosystem: Local advanced manufacturing for rapid fixtures, harnesses, short-run assemblies, and tooling to shorten iteration cycles and protect IP.

- Accommodation & amenities: 70 executive suites and an adjacent 500-room engineers’ precinct with entertainment and restaurants; sports oval and full exercise campus.

02

THE COMPETITIVE EDGE

- Harmonised evidence streams eliminate duplication and bespoke ETL—producing standards-aligned outputs reusable worldwide.

- Shared access to tunnels, EVSE energy houses, V2X infrastructure, and smart labs defers CapEx while boosting utilisation.

- Programmable adverse-condition testing removes weather delays, eliminates idle labour, and maximises asset productivity.

- Early DFM/DFA on shared digital twins reduces late engineering changes, tooling churn, and scrap.

- Airport adjacency lowers premium freight, dwell time, and line-stop contingencies; local manufacturing avoids tariffs and long shipping cycles.

- Independent SDV-TIC operations and on-site university consolidate witness days and travel, increasing engineer throughput while reducing overhead per program.

Net effect: Faster proof, fewer mules, fewer retests—globally portable evidence, sooner.

Cost Compression You Can Measure

- Harmonised evidence streams eliminate duplication and bespoke ETL—producing standards-aligned outputs reusable worldwide.

- Shared access to tunnels, EVSE energy houses, V2X infrastructure, and smart labs defers CapEx while boosting utilisation.

- Programmable adverse-condition testing removes weather delays, eliminates idle labour, and maximises asset productivity.

- Early DFM/DFA on shared digital twins reduces late engineering changes, tooling churn, and scrap.

- Airport adjacency lowers premium freight, dwell time, and line-stop contingencies; local manufacturing avoids tariffs and long shipping cycles.

- Independent SDV-TIC operations and on-site university consolidate witness days and travel, increasing engineer throughput while reducing overhead per program.

Accelerated Time to Market

- Common deterministic stack aligns development, testing, and certification—enabling parallel, cross-discipline validation with consistent evidence everywhere.

- Digital twin scenario libraries and virtual traffic management compress learning cycles—fewer redundant tests, higher coverage.

- Deterministic replay reduces validation mileage and driver hours—accelerating requirement closure and improving release confidence.

- Purpose-built SDV/OTA/EV capacity sustains continuous, year-round operations; programmable adverse conditions make critical validation predictable and schedule-friendly worldwide.

- Sovereign data backbone with blockchain provenance streamlines regulatory submissions, speeding assessments and reducing friction across jurisdictions.

- On-site SAE and IEEE partnerships align methods and skills with emerging standards—reducing method churn and witness-day overhead.

03

CONNECTED KNOWLEDGE

Managed by a Specialist SDV Provider

Recognising that legacy TIC providers cannot meet Mobility 5.0 demands, GONDWANA is founding a dedicated SDV-TIC Service Provider to operate the facility. By aggregating top-tier SDV expertise and modern methodologies, we deliver superior Testing, Inspection, and Certification services that accelerate SDV R&D, validation, and deployment.

Operating Model and Access

- Plug-and-play provisioning: Scientists, engineers, and technicians can be productive on day one with existing tools, methods, and standards.

- Flexible access models: Anonymous multi-tenant capabilities keep costs predictable while preserving IP.

- Sovereign data and compliance: Role-based access controls, tamper-evident evidence chains, and clock-synchronised data streams meet stringent confidentiality and compliance needs.

04

WHY AUSTRALIA, WHY NOW?

- Legacy capacity is constrained while SDV complexity, risk, and compliance are escalating.

- Australia provides political stability, sovereign data protections, a strong research base, modern infrastructure, and a skilled workforce—amplified by the on-site Mobility 5.0 university.

- The “secret sauce”: an interoperable, audit-ready, certification-grade evidence fabric embedded in a full-stack proving ground and supply-chain control plane—delivering faster cycles with higher assurance and unparalleled lower total cost.

Foundation Client Invitation

GONDWANA is in final design. Expressions of Interest for foundation clients include the opportunity to shape remaining technical specifications before design lock-down (Q4 2025). Operations commence Q4 2027. Allocation is first-in, first-served as capacity tightens.

You are not just testing vehicles—you are pioneering the future of mobility in collaboration with world-class facilities. It is first in, best dressed.

CONTACT: eoi@gondwana-australia.com

GONDWANA AUSTRALIA is engaging foundation clients now. Reach out to discuss capacity, specifications, and how G?MATRIX AI and the Mobility 5.0 proving ground align with your 2028 and beyond roadmap.

Strictly private and confidential

GET IN TOUCH

For information about our latest developments, or to make contact with the Gondwana project team, please send us a short note detailing your interest.